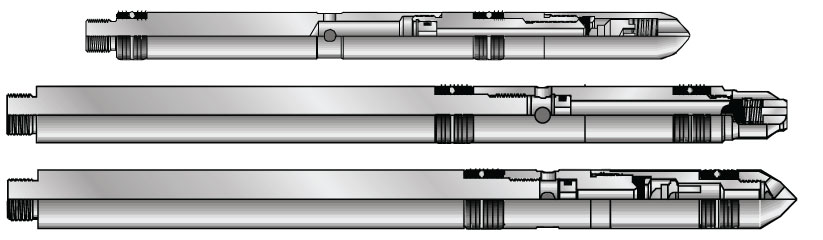

Retrievable Flow Control Devices

Wireline Retrievable Orifice Valves

The valve is designed with a square edged orifice which, when properly sized, allows volume control when the casing and the tubing pressures are known. An integral reverse flow check valve prevents reverse flow communication back through the valve.

APPLICATIONS:

These valves are used to establish communication between the tubing and annulus during circulating, gas, or fluid injection operations. They are utilized in single point injection continuous flow completions. These valves have no closing function and are commonly used to control stable injection at the operating valve depth.

FEATURES/BENEFITS:

• Replaceable floating square edged orifice (Tungsten Carbide insert available)

• Stainless steel or nickel alloys available for corrosion resistance in wells with high concentrations of H2S or CO2

• Flow capacity determined by orifice sizing

• Integral reverse flow check valve prevents reverse flow communication

• Standard Neoprene packing with other materials available

• Temperature rating of 250 F (121 C) (Standard service)

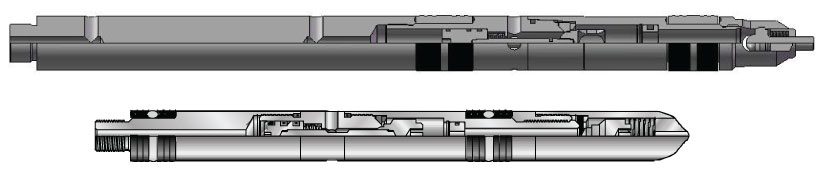

The valve is designed with a shear dart which is held in the closed position by a shear rod. The valve opens when the required differential casing annulus pressure is obtained and the shear rod parts allowing the shear dart to fall off seat and allowing flow through the valve. An increase of the pressure in the tubing over the casing pressure will not open the valve. The valve can be pre-set to shear at a minimum 1000 psi and up to a maximum of 4,000 psi shear pressure.

APPLICATIONS:

The selective isolation device when installed in a side pocket mandrel acts as a dummy valve to pack-off the communication ports in the mandrel pocket, yet retain the option of being able to circulate between the casing and the tubing without well intervention. Once opened, the selective isolation device cannot be closed down hole. If the operator requires the valve to be closed, the valve must be removed by wireline and redressed.

FEATURES/BENEFITS:

• Replaceable floating square edged orifice

• Stainless steel or nickel alloys available

• When required, valve can be remotely sheared without well intervention

• Dual Integral reverse flow check valve prevents reverse flow communication

• Tubing pressure will not shear or open the valve

• Standard Neoprene packing with other materials available

• Temperature rating of 275 F (121 C) (standard service)