Conventional Flow Control Devices

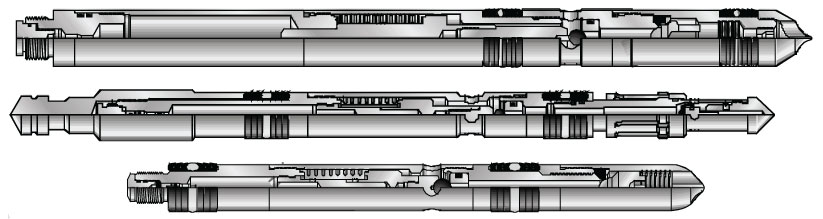

Conventional IPO Valves

The valve is designed with a sealed chamber and 3 ply bellows that contains a nitrogen charge, which provides the closing force of the valve. When injection gas pressure exceeds the closing force, the bellows compresses, lifting the ball stem off of the seat and allowing gas to be injected through the valve into the producing area.

APPLICATIONS:

For continuous flow or intermittent gas lift, tubing of annular flow applications.

FEATURES/BENEFITS:

• Stainless steel or premium materials available

• Three-ply nickel-copper alloy bellows

• Mechanical stop prevents bellows over stroke

• Bellows dampening fluid to prevent fatigue and stem-seat pounding

• Tungsten carbide ball

• Replaceable floating seat (Tungsten Carbide available)

• Integral reverse flow check valve to prevent casing to tubing flow

• Pressure rating up to 1,800 psi (124 bars) test rack opening pressure

• Integral reverse flow check valve with resilient and metal to metal seals

• Temperature rating of 250° F (121°C) (standard service)

• Standard neoprene packing with other materials available

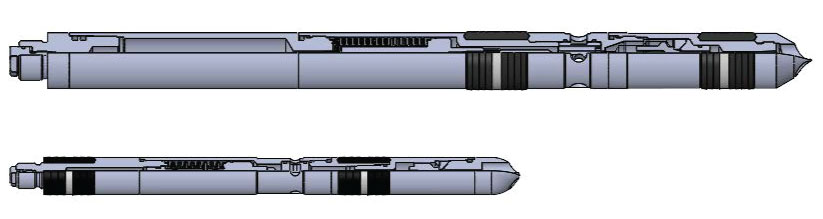

The valve is designed with a sealed chamber and 3 ply bellows that contains a nitrogen charge, providing the closing force of the valve. When injection gas pressure exceeds the closing force, the bellows compresses, lifting the ball stem off the seat and allowing gas to be injected through the valve into the producing area.

APPLICATIONS:

For continuous flow or intermittent gas lift, annular flow applications.

FEATURES/BENEFITS:

• Stainless steel or premium materials available

• Three ply nickel-copper alloy bellows

• Replaceable floating crossover seat

• Mechanical stop prevents bellows over stroke

• Bellows dampening fluid to prevent fatigue and stem-seat pounding

• Integral reverse flow check valve with resilient and metal to metal seal

• Pressure rating up to 1,800 psi (124 bars) test rack opening pressure

• Temperature rating of 250°F (121°C) for standard service

• Standard neoprene packing with other materials available