Conventional Flow Control Devices

Conventional Gas Lift Check Valves

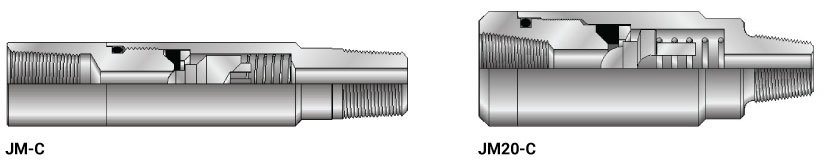

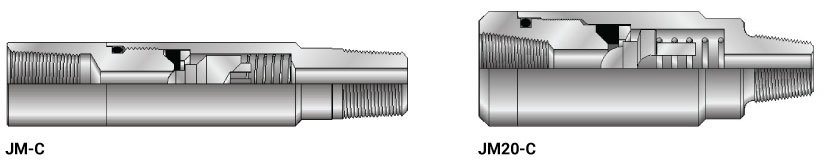

Check valves are used with conventional gas lift valve to protect the casing from backflow, allow for pressurizing the tubing in various procedures, and prevent any comingling of flow in dual installation. The conventional check assemblies utilize the same metal to metal seal as well as metal dart to soft pad seal as does the retrievable valve checks. The check is a velocity type check requiring flow pressure to force the dart on seat.

APPLICATIONS:

keep or delete this section?

FEATURES/BENEFITS:

• Keep or delete?

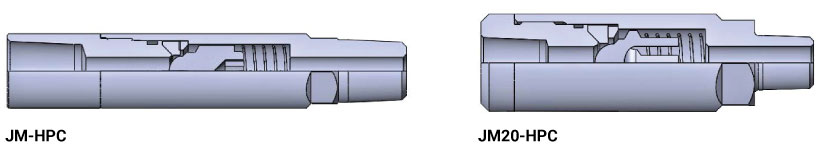

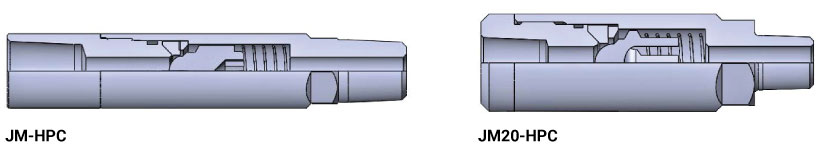

Check valves are used with conventional gas lift valves to protect the casing from backflow, allow for pressurizing the tubing in various procedures, and preventing communication of flow in dual installation. The JM-HPC and JM20-HPC conventional check assemblies have a 10,000 psi back-check rating. Both check valve assemblies utilize a premium moly-filled Teflon soft seal against a metal dart as well as metal-to-metal seal. The check is a velocity-type check requiring flow pressure to force the dart on seat.

APPLICATIONS:

keep or delete?

FEATURES/BENEFITS:

• Keep or delete?

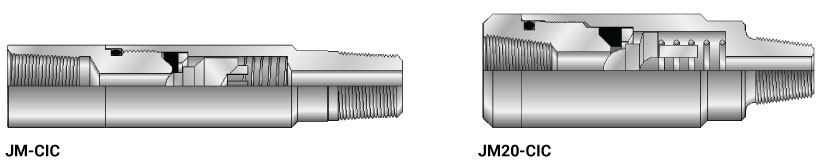

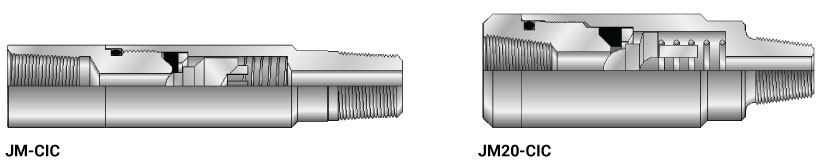

Chemical injection check valves are used with conventional chemical injection valves to protect the casing or control line from backflow, allow for pressurizing the tubing in various procedures, and prevent any comingling of flow in dual installation. The conventional chemical injection check assemblies utilize a metal to metal seal as well as metal dart to Teflon® pad seal. The check is a positive spring type check that retains the dart on seat.

APPLICATIONS:

keep or delete?

FEATURES/BENEFITS:

• Keep or delete?